When your heating and cooling system suddenly stops working on a sweltering Houston summer day or a rare cold snap, the discomfort can be overwhelming. The average American homeowner faces HVAC issues at least once every three to five years, and understanding what’s wrongand what the repair process looks likecan save you time, money, and stress. Whether you’re dealing with a furnace that won’t ignite or an air conditioner blowing warm air, knowing the common problems and repair expectations helps you make informed decisions and avoid costly mistakes.

Understanding Your Heat and Air System Components

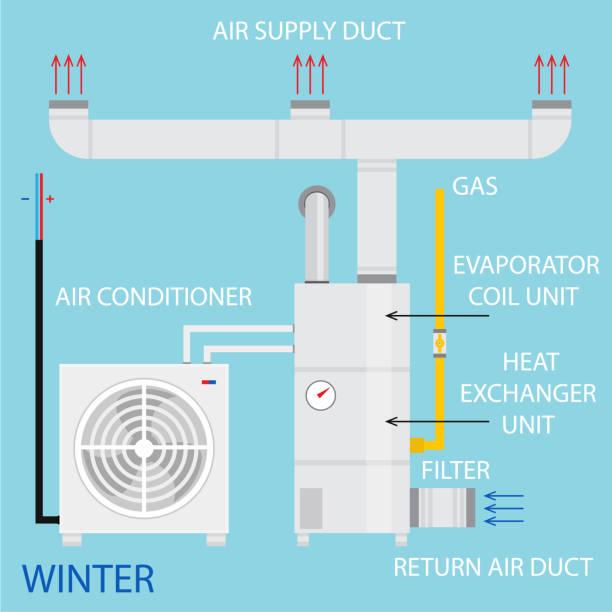

Before diving into common issues, it’s essential to understand what makes up your HVAC system. Your heating and cooling equipment consists of several interconnected components working in harmony to maintain comfortable indoor temperatures year-round.

The heart of your cooling system is the compressor, located in the outdoor unit, which pressurizes refrigerant to enable heat transfer. Inside your home, the evaporator coil absorbs heat from indoor air, while the condenser coil outside releases that heat to the environment. The air handler, containing the blower motor and fan, circulates conditioned air through your ductwork.

For heating, most Houston homes use either a gas furnace or an electric heat pump. Gas furnaces burn natural gas in a combustion chamber, transferring heat through a heat exchanger before distributing warm air via the blower. Heat pumps, increasingly popular in our climate, reverse the cooling process to extract heat from outdoor aireven in cold weatherand transfer it inside.

The thermostat acts as your system’s brain, monitoring temperatures and signaling when heating or cooling is needed. Modern smart thermostats can learn your preferences and adjust automatically, potentially reducing energy costs by up to 23% according to Energy Star data.

Most Common Heat and Air Repair Issues

Refrigerant Leaks and Low Refrigerant Levels

One of the most frequent problems AC repair technicians encounter is refrigerant issues. When your system is low on refrigerant, it’s not simply a matter of “topping it off”there’s likely a leak that needs addressing. Signs include ice formation on the evaporator coil, hissing sounds from the indoor unit, and significantly reduced cooling capacity.

Refrigerant leaks can occur due to corrosion in copper coils, vibration causing friction in line sets, or factory defects in evaporator or condenser coils. The Environmental Protection Agency reports that fixing refrigerant leaks not only improves efficiency but is also crucial for environmental protection, as many refrigerants are potent greenhouse gases.

Electrical Component Failures

Your HVAC system relies on numerous electrical components, and any failure can shut down your entire system. Common electrical issues include:

- Faulty capacitors that prevent motors from starting properly

- Worn contactors that fail to engage the compressor or fan motors

- Damaged wiring from rodents or age-related deterioration

- Tripped breakers due to electrical overload or short circuits

- Failed control boards that can’t properly sequence operations

According to industry data, electrical problems account for approximately 30% of all HVAC service calls, making them among the most common repair needs homeowners face.

Thermostat Malfunctions

Sometimes what appears to be a major HVAC problem is actually a thermostat issue. Dead batteries, incorrect settings, or faulty wiring can all cause your system to behave erratically. Modern programmable and smart thermostats, while offering excellent energy-saving features, can also experience software glitches or connectivity issues that affect performance.

Professional technicians report that roughly 15% of “no cooling” or “no heating” calls are resolved by simply recalibrating or replacing the thermostata relatively inexpensive fix compared to major component repairs.

Clogged Filters and Restricted Airflow

While it seems simple, a clogged air filter is responsible for countless HVAC problems. When airflow is restricted, your system works harder to maintain temperatures, leading to increased wear on components, higher energy bills, and potential system failure. The Department of Energy estimates that replacing a dirty filter can lower your air conditioner’s energy consumption by 5% to 15%.

Beyond filters, airflow restrictions can result from:

- Blocked or closed supply vents

- Damaged or disconnected ductwork

- Dirty evaporator or condenser coils

- Obstructed outdoor units from vegetation or debris

Furnace-Specific Problems

Heating systems face unique challenges, particularly in regions like Houston where they may sit idle for months. Common furnace issues include:

Ignition Problems: Modern furnaces use either electronic ignition or pilot lights. Electronic igniters can crack or fail over time, while pilot lights may go out due to drafts or thermocouple issues.

Heat Exchanger Cracks: This serious issue can release carbon monoxide into your home. Annual inspections are crucial for early detection, as replacement costs can range from $2,000 to $5,000.

Blower Motor Failures: Continuous operation during Houston’s long cooling season can wear out blower motors. Warning signs include unusual noises, weak airflow, or the motor cycling on and off frequently.

What to Expect During Professional Heat and Air Repair

Initial Diagnosis and Assessment

When you call for HVAC repair services, the process typically begins with a thorough system assessment. Experienced technicians follow a systematic approach to identify problems accurately.

The diagnostic process usually includes:

- Discussing your observations and symptoms with you

- Visual inspection of all accessible components

- Testing electrical components with multimeters

- Checking refrigerant pressures and temperatures

- Examining ductwork and airflow patterns

- Running system cycles to observe operation

Professional HVAC technicians emphasize the importance of complete diagnostics. As one industry expert notes, “Rushing to replace parts without proper diagnosis often leads to repeat failures and unnecessary expenses. A thorough assessment might take 30-60 minutes but saves hours of troubleshooting later.”

Repair Timeline Expectations

Repair timelines vary significantly based on the issue’s complexity and parts availability. Simple fixes like replacing capacitors or contactors typically take 30-60 minutes once diagnosed. More complex repairs, such as replacing evaporator coils or fixing refrigerant leaks, might require 2-4 hours or multiple visits.

Parts availability can significantly impact repair timelines. Common components are usually stocked on service vehicles, enabling same-day repairs. However, specialized parts for older systems or specific manufacturers might require ordering, potentially extending repairs by 1-3 days.

Cost Factors and Estimates

Understanding repair costs helps you budget appropriately and avoid surprises. Several factors influence the final price:

| Repair Type | Average Cost Range | Time Required |

|---|---|---|

| Capacitor Replacement | $150-$400 | 30-45 minutes |

| Refrigerant Leak Repair | $200-$1,500 | 2-4 hours |

| Blower Motor Replacement | $450-$2,000 | 2-3 hours |

| Control Board Replacement | $500-$1,200 | 1-2 hours |

| Evaporator Coil Replacement | $600-$2,000 | 3-5 hours |

Emergency service calls, typically needed during extreme weather or outside regular business hours, often include additional fees ranging from $75 to $200 above standard rates.

Prevention Strategies and Maintenance Tips

Regular Professional Maintenance

The most effective way to prevent costly repairs is through regular professional maintenance. The U.S. Department of Energy recommends annual tune-ups for both heating and cooling systems. During these visits, technicians perform comprehensive inspections, clean critical components, and identify potential issues before they become major problems.

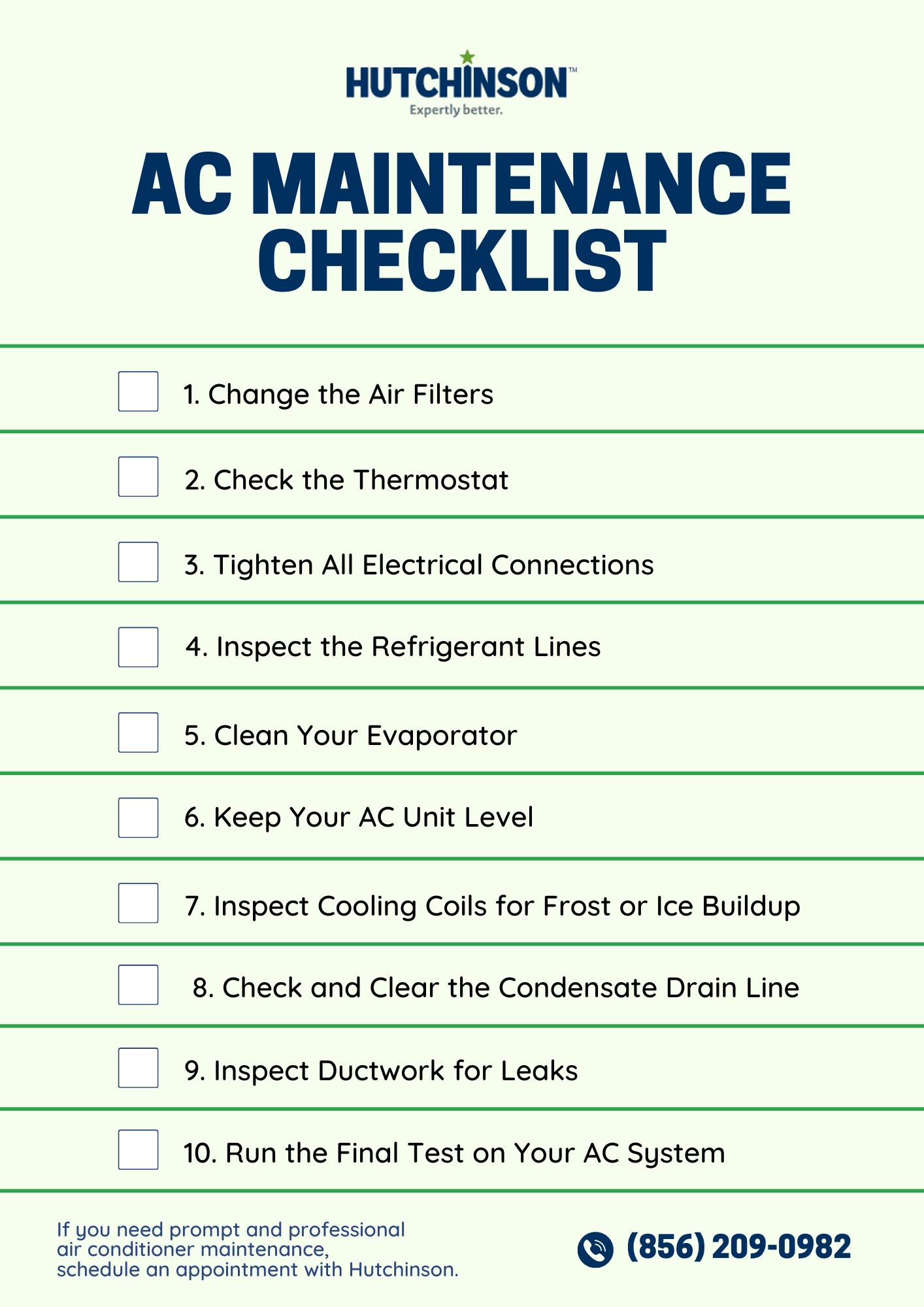

Professional maintenance services typically include:

- Cleaning or replacing air filters

- Inspecting and cleaning evaporator and condenser coils

- Checking refrigerant levels and testing for leaks

- Lubricating moving parts to reduce friction

- Testing electrical connections and tightening loose terminals

- Calibrating thermostats for accurate temperature control

- Inspecting ductwork for leaks or damage

DIY Maintenance Between Professional Visits

While professional maintenance is irreplaceable, homeowners can perform simple tasks to keep systems running efficiently:

Monthly: Check and replace air filters when dirty. During peak usage months, this might be necessary every 30 days, especially if you have pets or allergies.

Seasonally: Clear debris from around outdoor units, maintaining at least two feet of clearance. Trim vegetation that might restrict airflow or damage equipment.

Annually: Test your thermostat’s accuracy using a separate thermometer. Clean supply and return vents to ensure unobstructed airflow throughout your home.

When to Repair vs. Replace Your System

Deciding between repairing and replacing your HVAC system requires careful consideration of multiple factors. The general industry guideline follows the “$5,000 rule”multiply your system’s age by the repair cost. If the result exceeds $5,000, replacement might be more economical.

Consider replacement when:

- Your system is over 15 years old and requires frequent repairs

- Energy bills have increased significantly despite regular maintenance

- R-22 refrigerant is needed (phased out and increasingly expensive)

- Major components like compressors or heat exchangers fail

- Your home has comfort issues that repairs don’t resolve

Modern HVAC systems offer significant efficiency improvements. Energy Star certified equipment can reduce cooling costs by up to 20% compared to systems installed just 10 years ago. When considering AC replacement or new installation, factor in potential energy savings and available rebates or tax credits.

Choosing the Right HVAC Repair Service

Essential Qualifications to Look For

Selecting a qualified HVAC contractor ensures proper repairs and protects your investment. Key qualifications include:

Licensing and Certification: Texas requires HVAC contractors to hold state licenses. Additionally, look for NATE (North American Technician Excellence) certification, indicating advanced technical knowledge.

Insurance and Bonding: Proper insurance protects you from liability if accidents occur during repairs. Bonding provides financial protection if work isn’t completed as agreed.

Experience and Reputation: Established companies with years of local experience understand regional climate challenges and common system issues. Check online reviews and Better Business Bureau ratings for insight into customer satisfaction.

Red Flags to Avoid

Be cautious of contractors who:

- Offer quotes without inspecting your system

- Pressure you into immediate decisions

- Lack proper licensing or insurance documentation

- Request full payment before completing work

- Suggest replacing systems without explaining why repairs aren’t viable

Emergency Situations and Response

Some HVAC issues require immediate attention to prevent property damage or health risks. Recognize these emergency situations:

Gas Leaks: If you smell gas near your furnace, immediately shut off the gas supply, evacuate your home, and call your gas company from outside. Don’t use electrical switches or create sparks that could ignite gas.

Electrical Burning Smells: A burning electrical odor indicates potential fire hazards. Turn off your system at the breaker and contact an emergency repair service immediately.

Complete System Failure in Extreme Weather: When temperatures exceed 95°F or drop below freezing, system failures can pose health risks, particularly for elderly residents or those with medical conditions.

Frequently Asked Questions About Heat and Air Repair

How often should I have my HVAC system serviced?

Industry experts recommend professional maintenance twice yearlyonce before cooling season and once before heating season. In Houston’s climate, where air conditioning runs most of the year, spring AC tune-ups are especially critical for preventing summer breakdowns.

Why does my system freeze up even in hot weather?

Ice formation typically indicates airflow restrictions from dirty filters or low refrigerant levels. When airflow decreases, the evaporator coil temperature drops below freezing, causing moisture to freeze on the coils. This creates a cycle where ice further restricts airflow, worsening the problem.

Can I use any refrigerant type in my system?

No, you must use the specific refrigerant type your system was designed for. Mixing refrigerants or using incorrect types can damage components and violate EPA regulations. Older systems using R-22 cannot be retrofitted with R-410A without complete system replacement.

How long do HVAC repairs typically last?

Quality repairs by certified technicians should last the remaining lifetime of the component. Capacitors typically last 5-10 years, contactors 7-10 years, and motors 10-15 years with proper maintenance. If you experience repeated failures of the same component, underlying issues need addressing.

What’s covered under manufacturer warranties?

Most manufacturers cover parts defects for 5-10 years from installation date. However, warranties typically require professional installation, registration within 60-90 days, and annual professional maintenance. Labor costs usually aren’t covered unless you purchased an extended labor warranty.

Conclusion: Ensuring Reliable Comfort Year-Round

Understanding common heat and air repair issues empowers you to make informed decisions about your home’s comfort systems. From recognizing early warning signs to knowing what to expect during professional repairs, this knowledge helps you avoid emergency situations and unnecessary expenses. Regular maintenance remains your best defense against unexpected breakdowns, potentially extending system life by 40% according to ASHRAE studies.

The key takeaways for maintaining reliable heating and cooling include scheduling professional maintenance twice yearly, changing filters regularly, addressing minor issues before they become major problems, and working with qualified, licensed contractors for all repairs. By following these guidelines and understanding your system’s needs, you can ensure comfortable indoor temperatures throughout Houston’s challenging climate conditions while minimizing repair costs and maximizing equipment lifespan.

Don’t wait for a complete system failure to address HVAC concerns. Contact 75 Degree AC today at (713) 598-2737 for professional heat and air repair services. Our certified technicians provide honest assessments, upfront pricing, and reliable repairs that keep your home comfortable year-round. Schedule your service call now and experience the difference that local expertise and commitment to quality make.